Recycling and Sustainability in Battery Manufacturing

Navigating Towards a Greener Future

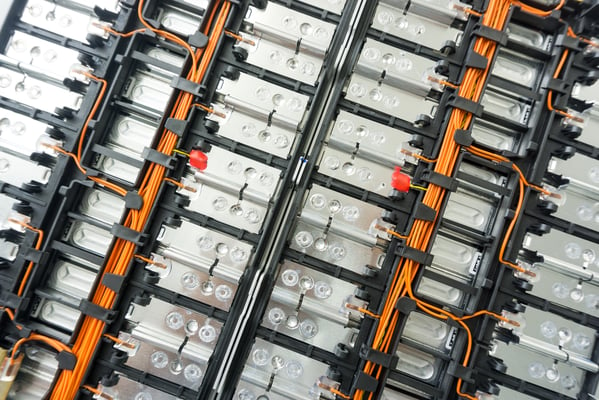

The rapid expansion of industries reliant on battery technologies, particularly within electric vehicles (EVs) and renewable energy storage, has led to a surge in demand for batteries. However, this growth has also raised concerns about the environmental impact and sustainability of battery manufacturing processes. Addressing these challenges has become increasingly urgent. This article examines the importance of recycling and sustainability practices in battery manufacturing and outlines the initiatives being taken to mitigate environmental impacts.

The Production Conundrum

Battery manufacturing traditionally follows a linear approach involving raw material extraction, energy-intensive manufacturing processes, and the disposal of spent batteries. This method contributes to resource depletion, pollution, and waste accumulation, posing significant environmental challenges. Moreover, the extraction of minerals such as lithium, cobalt, and nickel for battery production has raised ethical concerns regarding labor practices and human rights violations in mining regions.

Recycling as a Panacea

Recycling plays a pivotal role in mitigating the environmental impact of battery manufacturing. By recovering valuable materials from spent batteries, recycling reduces the need for raw material extraction, conserves resources, and minimizes waste generation. Additionally, recycling enables the recovery of critical metals like lithium, cobalt, and nickel, which can be reused in new battery production, thus creating a closed-loop system that reduces dependence on virgin materials.

Initiatives Driving Change

Numerous initiatives and programs are underway to promote battery recycling and sustainability in manufacturing. Collaboration between governments, industry stakeholders, and research institutions aims to develop efficient recycling technologies, establish collection and recycling infrastructure, and implement regulatory frameworks for proper disposal and recycling of batteries. Innovative approaches such as blockchain technology are also being explored to track the lifecycle of batteries, enhance transparency, and promote responsible sourcing and recycling practices.

Transitioning to Circular Economies

Transitioning to a circular economy model is crucial for achieving sustainability in battery manufacturing. This involves designing batteries with recyclability in mind, improving battery design for easier disassembly and material recovery, and incentivizing manufacturers to adopt sustainable practices throughout the product lifecycle.

The Future Landscape

The future of battery manufacturing hinges on adopting holistic approaches that prioritize sustainability, resource efficiency, and environmental responsibility. By embracing recycling initiatives, implementing circular economy principles, and investing in innovative technologies, the battery industry can minimize its environmental footprint and contribute to a more sustainable future. Governments, businesses, and consumers all play pivotal roles in driving this transition and fostering a circular economy for batteries.

Lithium-Ion Battery Recycling: Pioneering Sustainable Solutions

The electric vehicle (EV) revolution, fueled by the rise in lithium-ion batteries, has reshaped transportation and energy storage. However, this surge in demand has underscored the critical need for efficient and sustainable battery recycling. Understanding the present challenges, opportunities, and future prospects in lithium-ion battery recycling is essential for shaping a greener future.

Market Dynamics and Challenges

The International Energy Agency (IEA) projects a remarkable growth trajectory, forecasting a lithium-ion battery production capacity of 7 terawatt-hours (TWh) by 2030. This rapid expansion signifies a global manufacturing transformation. However, hidden within this growth lies a looming challenge.

The Lifecycle Predicament

Lithium-ion batteries, integral to EVs and various electronics, have a finite lifespan. Upon reaching the end of their lifespan, they pose environmental risks due to hazardous materials such as lithium, cobalt, and nickel. Without proper recycling, these batteries can end up in landfills, releasing toxic substances into the environment.

Navigating Toward Sustainability

Thankfully, there are diverse approaches to address this challenge:

- Reuse: Extending battery life by repurposing them for stationary energy storage offers a sustainable solution.

- Transformation: Repurposing old batteries into compact power units for electronics demonstrates environmental responsibility.

- Recycling: This crucial technique involves breaking down used batteries and extracting valuable metals and compounds, which are then utilized in new batteries, reducing reliance on fresh resources.

By embracing these methods, we can contribute to a more sustainable and responsible use of batteries.

The Importance of Lithium-Ion Battery Recycling

As the world transitions to electric mobility, lithium-ion battery recycling becomes imperative. With the rapid rise of electric vehicles (EVs) driven by climate change concerns, over 20 countries aim to either go fully electric or ban traditional gas-powered cars by 2030. This shift underscores the necessity of recycling used lithium-ion batteries to prevent environmental harm and address the looming shortage of raw materials required for new batteries.

Unlocking Value from Waste: The Recycling Journey

Various techniques are employed to reclaim valuable materials from used batteries:

- Direct Recycling: This method preserves battery components intact, ensuring high purity but encountering technical challenges.

- Hydrometallurgy: Using water-based solutions to extract metals, this approach is costly but flexible and widely recognized.

- Pyrometallurgy: This traditional method involves incinerating batteries to retrieve raw metal, raising concerns about air pollution and energy use.

Challenges Ahead

Efficient and widespread lithium-ion battery recycling faces several obstacles:

- Technical Hurdles: Current technologies struggle with the diverse and non-standardized nature of lithium batteries, impacting efficiency and yield.

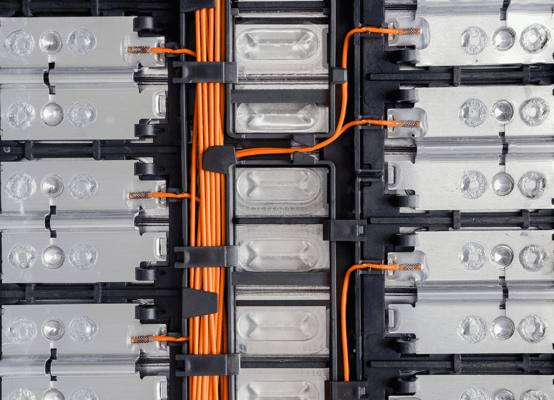

- Battery Design Complexity: Evolving intricate battery designs pose challenges in disassembly and pretreatment, necessitating adaptable technologies.

- Material Complexity: Managing mixed cathode materials and specific anode material requirements calls for innovative recycling solutions.

- Scaling Solutions: Bridging the gap between academic research and industrial application is critical for large-scale adoption.

Economic Considerations

The economic viability of recycling hinges on reclaiming valuable cathode materials like cobalt and nickel. Optimizing current technologies and reducing processing costs are essential to make large-scale adoption economically feasible.

Fostering Trust and Transparency

To incentivize major battery manufacturers to use recycled materials, rigorous testing and validation are necessary to ensure performance on par with or superior to virgin materials. Transparency and collaboration across the supply chain are vital for building trust and encouraging broader adoption of recycled materials.